Cleaning Up

LG Display is able to make this early loan repayment because the company finalized the sale of their Gen 8 LCD fab in Guangzhou, China to TCL (000100.CH) subsidiary Chinastar (pvt) on April 1. The sale generated 2.247 trillion won ($1.67b US), from which the loan will be repaid. The loan repayment represents ~44.5% of the fab sale proceeds. LG Display has also indicated that it will be signing an agreement with both the city of Paju and the province of Gyeonni called a ‘reshoring MOU’, which will give LGD ~50 billion won ($37m US) in investment subsidies and tax breaks for returning to local manufacturing only.

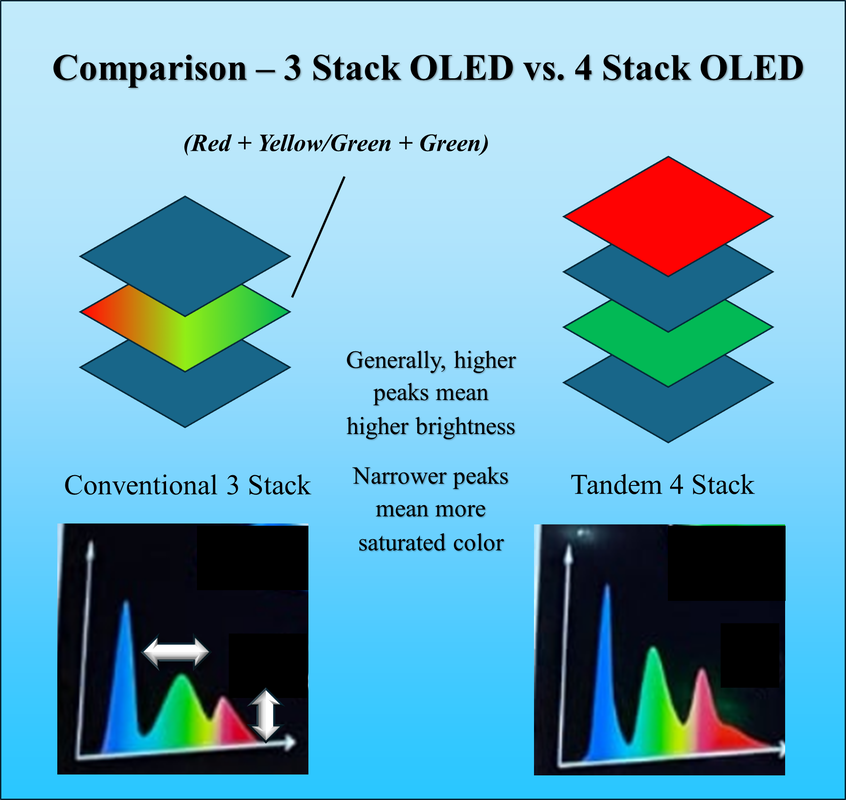

LG Display will use the onshoring subsidies and more of the fab sale proceeds to make 700 billion won ($517m US) improvements in existing and new OLED technology facilities. The company was not specific about the actual investments, but it is thought that some of the unoccupied space at the Paju complex will be converted into small/medium panel capacity, perhaps to allow LGD to capture a larger share of Apple’s (AAPL) smartphone and tablet business. That said, as of yet, there has been no mention of the construction of Gen 8.6 IT OLED lines, the same as those being built by Samsung Display (pvt) and BOE (200725.CH) currently. LG Display currently produces IT panels on less efficient Gen 6 lines, but has been the leader in the production of tandem OLED display panels, those used by Apple in the iPad Pro.

We doubt, even after the sale of the Guangzhou LCD fab, that LG Display is going to commit to a full-scale Gen 8.6 OLED IT fab, which we expect will cost between $3 billion and $6 billion, depending on capacity. While producing IT OLED displays on Gen 6 lines might not be as cost efficient, we believe LG Display is further along in the commercialization and manufacturing cycle than its competitors. Samsung Display will have to go through a period of low yield as it begins to bring its Gen 8.6 IT OLED line into production next year and that will likely maintain LG Display’s tandem OLED advantage through 2026. Both SDC and BOE are taking the risk that the additional capacity brought on by these two new Gen 8.6 OLED IT fabs will get absorbed by customers relatively quickly, but we expect LGD, after many quarters of losses, is not quite ready to take that risk.

RSS Feed

RSS Feed